By William Pearce

In the early 1900s, Lorraine-Dietrich was a French manufacturer of wagons, rail equipment, and automobiles. During World War I, the company’s factory in Argenteuil, France started manufacturing aircraft engines under the name “Lorraine.” The Argenteuil factory was led by Marius Barbarou, the engineer that designed the aircraft engines.

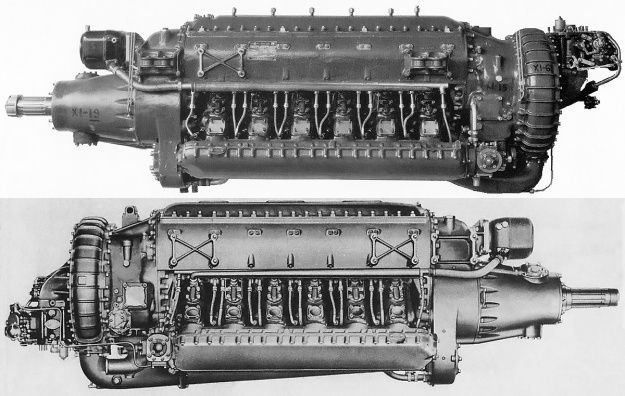

The Lorraine 12F of 1919 was the first of the company’s W-12 engines and followed the design outlined in the 1918 patent. Note the exposed pushrods and enclosed valves.

By 1918, Lorraine had developed aircraft engines in the form of an inline-six, a V-8, and a V-12. However, Barbarou began to experiment with engines of a W configuration. The W (or broad arrow) engine configuration had the benefit of being more rigid and slightly lighter than a comparable V-12, with the drawback of being slightly taller and wider. On 5 June 1918, Lorraine (under Barbarou) applied for a patent in which the benefits of a W engine with either four, six, or eight cylinders per bank was described. While the British Napier Lion W-12 was being developed at the same time, the patent illustrates that the Lorraine W engines were a parallel development and not a copy of the Lion. French patent 504,772 was awarded on 22 April 1920 for the W engine design.

The first generation of Lorraine’s W engines was designed around 1918 and known as the 12F (many sources do not give a designation for this engine, and “12F” was used again). The liquid-cooled, 12-cylinder engine consisted of a two-piece aluminum crankcase that was split horizontally along the crankshaft’s axis. Three banks of cylinders were mounted atop the crankcase, and the left and right banks were angled 60 degrees from the center, vertical bank. Each cylinder bank had two pairs of two cylinders. Each pair of steel cylinders was surrounded by a welded steel water jacket. Atop each cylinder was a single intake valve and a single exhaust valve. The enclosed valves were each actuated by a partially exposed rocker and a fully exposed pushrod. All of the pushrods were controlled by two camshafts—one positioned in each Vee between the cylinder banks. The push rods that controlled the exhaust valves for the left and right cylinder banks had a lower roller rocker that followed the camshaft.

A single-barrel updraft carburetor was positioned on the outer side of the right cylinder bank. An intake pipe led from the carburetor, passed between the two cylinder pairs of the right bank, and joined a manifold. The manifold split into four branches that fed each of the cylinders on the right bank. Employing a similar configuration, a two-barrel carburetor on the left side of the engine fed both the left and center cylinder banks. Each cylinder had two spark plugs that were fired by two magnetos located at the rear of the engine. The left magneto fired the spark plugs on the intake side of the cylinders, and the right magneto fired the exhaust-side spark plugs.

With a new crankcase, crankshaft, and camshafts, the 24-cylinder 24G of 1919 was more than just two 12F engines coupled together. Note the ignition system driven from the propeller shaft.

The flat-plane crankshaft had four throws and was supported by three main bearings. A master connecting rod was attached to each crankpin. The master rods were connected to the aluminum pistons in the vertical cylinder bank. Articulated rods connected the pistons in the left and right cylinder banks to the master connecting rods. The engine had a compression ratio of 5.2 to 1. The propeller was attached directly to the crankshaft without any gear reduction. The Lorraine 12F had a 4.96 in (126 mm) bore and a 7.09 in (180 mm) stroke. The W-12 engine displaced 1,826 cu in (29.9 L) and produced 500 hp (372 kW) at 1,600 rpm. The 12F weighed 960 lb (435 kg).

While work on the 12F was underway, a 24-cylinder engine was designed that was basically two 12Fs. The W-24 engine was designated 24G (many sources do not give a designation for this engine, and a different G-series emerged later). Other than having twice the number of cylinders, the main change from the 12F was that the ignition system was driven at the front of the engine. The 12G’s eight throw crankshaft was supported by five main bearings. The W-24 engine displaced 3,652 (59.9 L) and produced 1,000 hp (746 kW) at 1,600 rpm. The direct drive engine weighed 1,874 lb (850 kg), and it was estimated that a 16 ft 5 in (5 m) propeller would be needed to harness its power.

The 12F and 24G engines were built during 1919 and displayed at the Salon de Paris in December of that year. There is some indication that the valve arrangement was problematic at high engine speeds, but the engines were displayed at the next two Salons in November 1921 and December 1922. No applications are known for the 12F or the 24G, which were too large for almost all aircraft. It is unlikely that more than a few of these engines were built.

A direct-drive 12E-series engine with exposed valves and overhead camshafts. Unseen are the magnetos positioned at the rear of the engine.

While enduring the rough start with the first generation of W engines, Barbarou had already designed the second generation—starting with the 12E-series. The first engine in this series was the 12Ew, which was derived from the 370 hp (276 kW) Lorraine 12D (V-12) and conceived to fill the power gap between that engine and the 500 hp (373 kW) 12F. The 12Ew was similar in layout to the 12F, but had a completely different valve arrangement. The exposed valves for each cylinder bank were actuated via rockers by a single overhead camshaft. The camshaft was driven by the crankshaft via bevel gears and a vertical shaft at the rear of the engine. It appears that the two magnetos were initially located at the front of the engine but later relocated to the rear of the engine. The engine had a compression ratio of 5.5 to 1. The propeller was attached directly to the crankshaft without any gear reduction.

The Lorraine 12Ew had a 4.72 in (120 mm) bore and a 7.09 in (180 mm) stroke. The engine displaced 1,491 cu in (24.4 L) and produced 420 hp (313 kW) at 1,800 rpm. The 12Ew was 54.1 in (1.37 m) long, 47.6 in (1.21 m) wide, and 44.8 in (1.14 m) tall. The engine weighed around 860 lb (390 kg). The 12Ew was first run around late 1919, but development was slowed due to work on other engines and other projects. The 12Ew was used in a few aircraft, and the engine was developed into the 12Eb.

The Lorraine 12Eb was dimensionally the same as the 12Ew, but it had a compression ratio of 6.0 to 1 and produced 450 hp (336 kW) at 1,850 rpm. The engine weighed 822 lb (373 kg). The 12Eb was first run in late 1922 or early 1923, and 30 test engines were built in 1923. The 12Eb quickly proved itself to be a successful engine. In March 1924, the 12Eb was the most economic engine at an endurance competition (Concours de Moteurs de Grande Endurance) held at Chalais-Meudon, near Paris. The engine operated for a total of 410 hours at 1,850 rpm. During that time, three cylinders were replaced due to water leaks.

A 12Eb engine with the magnetos driven from the front of the engine. Power from the magnetos was taken to the distributors, which were driven by the back of the left and right cylinder bank camshafts. (Pline image via Wikimedia Commons)

12Eb production started in late 1924, and approximately 150 engines were built in 1925. From 1924 to 1927, a number of licenses were purchased by other countries to manufacture the 12Eb: CASA and Elizalde in Spain; SCAT in Italy; FMA in Argentina; Hiro, Nakajima, and Aichi in Japan; PZL in Poland; Škoda and ČKD in Czechoslovakia; and IAR in Romania. The Blériot-SPAD S.61 fighter, the Breguet 19 light bomber, and the Potez 25TOE reconnaissance bomber were the 12Eb’s primary applications.

In 1925, a geared version of the 12Eb was developed, and it was designated 12Ed (sometimes referred to as 12Ebr). The planetary gear reduction turned the propeller at .647 times crankshaft speed. At 59.9 in (1.52 m), the 12Ed was 5.8 in (.15 m) longer than the direct-drive engine. Engine weight also increased 86 lb (39 kg) to 908 lb (412 kg). The 12Ed produced the same 450 hp (336 kW), but this was achieved at 1,900 engine rpm and 1,226 propeller rpm. The main application for the 12Ed was the CAMS 37 reconnaissance flying boat.

The 12Ed engine with a propeller gear reduction was the same basic engine as the 12Eb. The early engines had a smooth gear reduction housing, but ribs were added later for extra strength.

The 12Ee debuted in 1926. This engine was basically a 12Eb with its compression ratio increased to 6.5 to 1. The 12Ee produced 480 hp (358 kW) at 2,000 rpm and had a maximum output of 510 hp (380 kW). The engine weighed 846 lb (383 kg). The 12E-series engines were used in the FBA-21 flying boat and Villiers IV seaplane to set numerous seaplane payload and distance records. Lorraine built around 5,500 E-series W-12 engines, and licensed production added another 1,775, for a total of approximately 7,275 engines. In all, the 12E-series engines were used in around 24 countries.

In December 1926, a Lorraine W-18 engine was displayed at the salon de l’Aviation in Paris. The 18-cylinder engine was designated 18K, and it was based on the E-series. The engine had been under development by Barbarou since at least 1923. The 18K had individual cylinders, rather than the paired units used on the E-series. The cylinder banks had an included angle of 40 degrees. Each of the cylinder banks had two carburetors, with each carburetor feeding three cylinders. Otherwise, the induction system was similar to that used on the 12E, including the two barrel carburetors on the left side of the engine for the left and center cylinder banks. The 18K had a compression ratio of 6.0 to 1, and its crankshaft was supported by seven main bearings.

The Lorraine 18K had the same 4.72 in (120 mm) bore and a 7.09 in (180 mm) stroke as the 12E-series engines. The W-18 engine displaced 2,236 cu in (36.6 L) and weighed around 1,287 lb (584 kg). The 18Kb was the direct drive variant that produced 650 hp (485 kW) at 2,000 rpm. The engine was 79.2 in (2.01 m) long, 36.2 in (.92 m) wide, and 43.3 in (1.10 m) tall.

The 18K engine had the same construction as the 12E engines but used individual cylinders. Note that each carburetor fed two inductions pipes—one supplied the left cylinder bank and the other the center bank. The two one-piece magneto/distributor units are driven from the camshaft drive.

A version with a propeller gear reduction was designated 18Kd. The 18Kd turned the propeller at .647 times crankshaft speed and produced up to 785 hp (585 kW) at 2,500 rpm, but its continuous rating was the same as the 18Kb. With a total length of 83.5 in (2.12 m), the 18Kd was 4.3 in (109 mm) longer than the direct drive variant. The 18Kd weighed 1,365 lb (619 kg).

The 18Kd underwent official trials in mid-February 1927, and it was selected for the single-engine Amiot 122 bomber. The 18K may have been installed in other prototype aircraft, but the Amiot 122 was its only production application. A total of approximately 100 18Kb and 18Kd engines were made, and it was not considered a commercial success.

In 1928, Barbarou and Lorraine developed the third generation of W-12 engines, known as 12Fa Courlis. This was a reuse of the “12F” designation that was first applied in 1918. The F-series Courlis engines had a crankcase similar to that of the E-series, but the cylinder bank was a monobloc aluminum casting with enclosed valves. The steel cylinder liners were screwed into the cylinder banks, and the engine’s compression ratio was 6.0 to 1. Compared to the 12E, the cylinder bore diameter was increased, and the stroke length was decreased. Each cylinder had two intake and two exhaust valves, all actuated by a single overhead camshaft. The intake and exhaust ports were on the same side of the cylinder bank, and the carburetors mounted directly to the cylinder bank. The crankshaft was supported by five main bearings.

The Lorraine 12Fa Courlis had a 5.71 in (145 mm) bore and a 6.30 in (160 mm) stroke. The engine displaced 1,944 cu in (31.7 L) and produced 600 hp (447 kW) at 2,000 rpm. Sources indicate that the engine was capable of 765 hp (570 kW) at 2,400 rpm. Without gear reduction, the 12Fa Courlis was 62.2 in (1.66 m) long, 44.9 in (1.14 m) wide, 41.7 in (1.06 m) tall, and weighed 933 lb (423 kg). While the .647 propeller gear reduction did not increase the engine’s length by any noteworthy value, it did add 59 lb (27 kg), resulting in a weight of 992 lb (450 kg).

With its enclosed valves and monobloc cylinder banks, the 12Fa Courlis was a modern engine design when it appeared in 1929. The gear reduction mounted to the crankcase in place of the direct-drive propeller shaft housing. The rest of the engine, including the crankshaft, was the same between the direct drive and geared variants.

The 12Fa Courlis was first run around 1928 and was tested by the Ministére de l’Air (French Air Ministry) from 10 to 17 June 1929. During the test, 52 hours were run at 2,000 rpm. In July 1929, the 12Fa made its public debut at the Olympia Aero Show in London. The French authorities officially approved the engine for service on 21 August 1929. The 12Fa was installed in a Potez 25 for engine development tests, which were conducted in 1930.

Developed in 1930, the 12Fb Courlis had a simplified induction system compared to the 12Fa. The 12Fb Courlis had a single, three-barrel carburetor mounted at the rear of the engine. Three separate intake manifolds extended from the carburetor, with one manifold connecting to each cylinder bank. The engine had cross-flow cylinder heads, with the exhaust ports on the side opposite of the intake ports. The 12Fb had the same basic specifications as the 12Fa, but fuel delivery issues initially reduced its rating to 500 hp (372 kW) at 1,900 rpm. However, continued development of the 12Fb soon brought its power up to 600 hp (447 kW) at 2,000 rpm, the same as the 12 Fa. Although installed in a few prototypes, the 12Fb did not power any production aircraft. By the early 1930s, air-cooled radial engines were increasing in popularity for transports and liquid-cooled V-12 engines for fighters. The Lorraine F-series Courlis did not find the success of the E-series. Around 30 F-series Courlis engines were built.

The 12Fb had a simplified induction system with one carburetor and three intake manifolds. However, unequal fuel distribution was an issue.

Around 1932, an updated 12Eb was designed that incorporated some features from the 12F-series. Designated 12E Hibis, the engine used aluminum four-valve heads similar to those employed on the 12F engines. The Hibis had a 4.80 in (122 mm) bore and a 7.09 in (180 mm) stroke. The engine’s total displacement was 1,541 cu in (25.3 L), and it produced 500 hp (373 kW) at 2,000 rpm. While the engine was proposed around 1932, it is not clear if any were actually produced. The Hibis had disappeared by 1934.

In 1930, Barbarou created the 18-cylinder Lorraine 18Ga Orion. This W-18 engine combined the configuration of the 18K and the improved construction techniques of the F-series Courlis engines. The 18Ga had three monobloc cylinder banks set at 40 degrees. Each bank had six cylinders with a single overhead camshaft that operated the four valves per cylinder. The left and right cylinder banks had their intake and exhaust ports on their outer side. The carburetors were also mounted directly to the outer side of the cylinder bank. The center cylinder banks had a crossflow head with the carburetor and intake ports on the left side and the exhaust port on the right side. The crankshaft was supported by seven main bearings, and the engine had a .647 planetary gear reduction. It does not appear that there was a direct-drive variant.

The 18Ga Orion combined the 18-cylinder 18K engine with the modern construction of the 12F-series. Note that the outer cylinder banks have intake and exhaust ports on the same side, while the center cylinder bank has intake and exhaust ports on opposite sides.

The 18Ga Orion had a 4.92 in (125 mm) bore and a 7.09 in (180 mm) stroke. The engine displaced 2,426 cu in (39.8 L) and produced 700 hp (522 kW) at 2,100 rpm and 870 hp (649 kW) at 2,500 rpm. The W-18 engine was 83.1 in (2.11 m) long, 36.6 in (.93 m) wide, and 43.7 in (1.11 m) tall. The engine weighed 1,252 lb (568 kg). The 18Ga completed a 50-hour type test prior to its public debut at the salon de l’Aviation in Paris in November 1930. The engine was used in at least one prototype aircraft, the Amiot 126 bomber. The 18Ga did not enter production, and only around 10 engines were built.

In November 1934, a supercharged version of the 18G Orion was displayed at the salon de l’Aviation in Paris. An updraft carburetor fed the gear-driven, centrifugal supercharger that was mounted to the rear of the engine. Three intake manifolds delivered the air and fuel mixture to the cylinder banks, just like the 12Fb engine. The revised cylinder banks included four valves per cylinder that were actuated by dual overhead camshafts. Each camshaft pair was driven by a vertical shaft at the rear of the engine. The supercharged 18G produced 1,050 hp (783 kW) at 2,150 rpm, but no additional specifications have been found.

A few 12E-series engines are preserved in various museum. No Lorraine F-series, 18-cylinder, or 24-cylinder engines are known to exist.

The supercharged 18G Orion that was debuted in November 1934. Note the appearance of the new cylinder banks, which included four valves per cylinder.

Sources:

– Lorraine-Dietrich by Sébastien Faurès Fustel de Coulanges (2017)

– Aerosphere 1939 by Glenn D. Angle (1940)

– Les Moteurs a Pistons Aeronautiques Francais Tome I by Alfred Bodemer and Robert Laugier (1987)

– Le moteur Lorraine 12 Eb de 450 ch by Gérard Hartmann (undated)

– Moteur “Lorraine” 450 C.V. 12 Cylinders en W by Société Lorraine (circa 1925)

– Les Moteurs Lorraine by Société Générale Aéronautique (circa 1932)

– Moteur “Lorraine” 600 CV (Type 12 Fa.) by Société Lorraine (10 November 1929)